SMART ENTRY

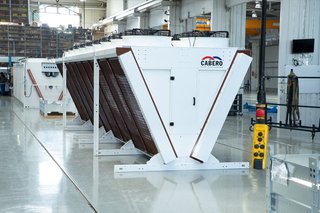

THE NEW "WALK IN" CONCEPT FROM CABERO

Principle

The search for a smart solution was aimed at operators, specialists and service personnel, with the aim of finding an ergonomic solution that is also environmentally friendly.

V-shaped heat exchangers are designed so that the heat exchangers are arranged at a specific angle to each other. Fans are positioned above between the heat both exchangers to ensure effective forced ventilation.

The integration of "walk-in" solutions into these systems marks a decisive step towards simplifying maintenance work.

In these applications, the fans are always mounted on the "roof" of the appliance, which means that the hinged fan nozzles must always be opened for maintenance work on the appliance. There is no access for service personnel to the interior of the appliance in almost all standard market designs. As most appliances do not have non-slip surfaces in the running area, stepping onto the roof areas of the appliances poses considerable risks and requires safety measures such as belts, certified fall protection, platforms, etc. These measures are particularly costly and time-consuming. These measures are particularly complex and cost-intensive, especially when you consider that most of these heat exchangers have been and will continue to be installed on the roof surfaces of buildings.

With hinged nozzles, the service personnel must clean the heat exchanger from the open fan plate/fan with a long spray bar, the length of which must correspond to the height of the heat exchanger. Many of the heat exchanger surfaces, especially in the upper corner areas, are not accessible and are therefore difficult to clean using this method. Dipping upside down is often the only option, which in turn represents an extremely dangerous situation for service personnel, especially in adverse weather conditions.

A "walk-in" solution with service doors ensures that access is always via existing, secured service platforms or via the roof area of the building.

Stay informed

1

Improved access: The use of walk-in design with service doors allows direct access to the internal components of the heat exchanger, which makes inspection and cleaning much easier. As the service technician is in an enclosed but well-ventilated space, there is no need for fall protection.

In addition, highly efficient maintenance with standard 30-50 cm spray bars not only respects the correct handling of the injection angles (to avoid possible damage from high pressure on the fins), but also ensures efficient and improved cleaning right into the "last corner" of the heat exchanger.

2

3

"Walk-in" occupational safety: Maintenance can be carried out more safely as the risk of injury from moving parts such as hinged fan plates is eliminated. In addition, the risk of falling is significantly reduced using anti-slip class R13 walk-on grilles, which offer safety even when wet.

To further reduce the carbon footprint, Cabero also ensures that these grilles are made from recycled materials and are therefore manufactured in an environmentally friendly way as far as possible.

In contrast to systems with hinged fan panels / fans, where service technicians have to work at heights of 2.4 to 2.8 meters and secure themselves against falling, walk-in solutions allow access at ground level.

Health and safety is a crucial aspect that is taken into account when designing heat exchangers with "walk-in" solutions using service doors and non-slip service aisles. Direct access reduces the risk of accidents during maintenance work. Compared to hinged fans, where there is a risk of workers getting trapped or pushed when opening and closing, slipping and injuring themselves on the unit or even falling off, walk-in designs offer a safer alternative. Walk-in solutions with service doors improve safety for maintenance personnel by providing a safer and more controlled environment for inspections and repairs, and largely protect against wind and weather.

4

5

Less downtime: Faster and safer maintenance means less downtime, which in turn increases operational efficiency.

The additional work involved with hinged fan plates / fans should not be underestimated. In addition to the extra time required for opening and closing, special tools or aids can also make maintenance work more complicated. In addition, two service technicians are often required to open the nozzles, which considerably increases the working time and the safety of the service staff.

6

7

8

9

10

The integration of WALK IN versions with service doors in V-shaped finned heat exchangers represents a significant improvement in day-to-day maintenance. This not only increases the safety and efficiency of maintenance work, but also reduces operating costs, protects the environment and confirms Cabero's Code of Conduct in practice. Such smart solutions are in line with ESG regulations and promote highly sustainable products for operators and customers. This solution is an important step towards the ergonomic and sustainable operation of cooling systems and their use at drycoolers and condensers.