and four car parking spaces represent?

MOORENWEIS

New construction of the company headquarters with 1,600 m2 of office space.

for mushroom cultivation

CABERO as a leading manufacturer in Asia

Optimum conditions for healthy mushroom growth

Highest efficiency, durability and hygiene standards

Green footprint thanks to innovative refrigerants

Global expertise - focus on Asia

Inselspital Bern

Like Swiss clockwork

From the introduction to many years of operation

Welcome aboard the Heliswiss helicopter!

WE ARE HIRING

A career with the CABERO Group

»Extraordinary people seek extraordinary challenges!«

Stay informed

Groundbreaking ceremony new headquarter for the CABERO sales group

Location

Stay informed

Groundbreaking ceremony for the new production unit for finned heat exchanger in China

Stay informed

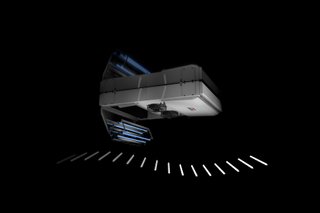

It's not just our customers who jump into the air

»Actually, it was my goal to become a pilot after the German Bundeswehr and not a manufacturer of heat exchangers!« Says Tino Cabero. »That is why I am so impressed by Heliswiss's flying skills.«

What the pilots achieve with this installation, with these wind conditions, the excess length of the load rope, which reduces the strong air turbulence of the rotor blades on the ground and in the almost blind interaction with the crew on the ground, is simply spectacular!

This flying ability is the premier class of commercial aviation, especially when you have 3.5 ton CABERO quality on the hook. 4,000 HP are distributed over 2 turbines that drive the coaxial double rotor system.

This is the heavy-duty helicopter Kamov KA 32 A12 HB-XKE which Heliswiss has modified not only in avionics and flight instruments.

»I believe that future discussions about the robustness and the extraordinary construction, which allows only four suspension points to be used with an 11 meter V-shaped unit, can be skipped with the CABERO products. Apart from a few scratches, which could be touched up with a touch-up pen, we had nothing!«

The most important thing, however, was that the units did not have any leaks after transport and set up thanks to STES from CABERO (Safety Tube Expanding System). STES avoids the contact between the pipes carrying the medium and the heat exchanger sheets and thus leakages due to possible abrasion during operation, as well as serious damage during installation and transport, are completely prevented.

»I would like to have: “Come fly with me” by Frank Sinatra as music - but the marketing department vetoed it!«

»A Frank Sinatra fan can still hear it while watching!« Tino Cabero smiles and adds, »I'm excited to see who will recognize the dangerous handle where a heat exchanger should never be touched when force is necessary during installation. If you can tell me, I will personally make you a cocktail at our stand at Chillventa or ISH!« concludes Tino Cabero.

Write to us and we will be happy to forward it to Mr. Cabero.

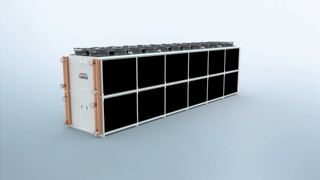

CABERO insulated cooler wall and penthouse

So-called insulated coolers are increasingly being used, particularly in the refrigeration redesign of existing cold stores.

The insulated coolers are used for the storage of food in normal and deep-freeze areas. The insulated coolers are always installed outside, i.e. outside the cooling room. As a result, the storage space can be used more effectively.

- No additional load on the existing statics

- No heat input into the cold room during defrosting

- Good service access

- And many more

Insulated cooler - Wall

Insulated coolers are flanged to the side walls of the cold stores. Due to their own steel platform, these hardly burden the existing or planned building statics.

The evaporator / air cooler is located in the cooling cell, with the forced ventilation in an axial or radial design being installed above or to the side of the heat exchanger.

Typical of this design is the flap, which protrudes into the cold room, as well as the inclined floor with a channel for defrosting water. The flap is closed during defrosting.

The air direction in this design is always horizontal.

Insulated cooler - Penthouse

The Penthouse version, on the other hand, are installed on the roof and allow the operator to position the cold source in the cold store in an advantageous manner. Here, too, the evaporator with blinds on both sides is installed in the middle of the cooling cell.

Normally this version does not have an insulated floor, since the air is drawn in on one side of the evaporator / air cooler via the "floor" and the fans are installed on the other side. However, there are air ducts with horizontal air inlet and vertical air outlet.

According to the version, the insulated and penthouse coolers are designed with cold panels between 160-200 mm as standard. A weather protection roof is mandatory and can be supplied by Cabero on request.

Since defrosting takes place with the flap closed (wall) or blind (penthouse), the defrosting heat does not get into the refrigerator. In addition, the formation of steam in the cold room is avoided, which would normally lead to icing on the ceiling. Thanks to the fact that it can be walked on, cleaning and service operations can be made considerably easier and more efficient, particularly for wall insulators.

The insulated coolers can be designed for all refrigerants. As a standard, Cabero offers cooling capacities of 50-400 kW, depending on the refrigerant and operating points.

CABERO regulation and control technology CRS

The operator can set a constant room temperature and the defrost cycles are carried out automatically according to certain control parameters. In addition to remote maintenance, evaluation and readjustment of the control parameters and program updates, this technology also allows the integration of a master-slave control.

Stay informed

CABERO FALL PROTECTION

CABERO integrates this option constructively in almost all outdoor units

Most of the time, outdoor units such as condensers and dry coolers are set up at "lofty heights". For service operations such as On fans, the operator is required to comply with the accident prevention regulations (for Germany UVV), which also apply to industrial plants and machines, due to the execution of installation.

CABERO has several solutions for this, which in addition to the rope fall protection system also provide more railings.

CABERO has taken this trend into account and provided almost all outdoor units with optional mounting systems for such railings.

According to the DIN standards, in addition to the own weight of the railing, horizontal and vertical loads must also be calculated, which can be caused by wind, people or leaning.

Loads in the standard (all-round railing per device) of up to 0.5 kN / m (corresponding to around 50 kg per meter of railing) were provided. However, higher loads such as for example 1.0 kN / m can also be met on request.

As experience shows, the requirements and the layout of such railings are different for each project. Often several devices are combined or only a certain side of a device is provided with a railing.

The special designs required may need to be redesigned. In these cases, it has always proven useful to work with the client's structural engineer in order to be able to exclude possible risks.

Fall protection air intake

With the V-shaped outdoor units, railings can also be provided as fall protection on the sides of the heat exchangers in the absence of step grids.

The fall protection option should be announced when ordering. In most cases, retrofitting is feasible, but this is almost always associated with higher labor cost.

As a standard, the railings are made of hot-dip galvanized steel with a horizontal rung in the middle. Optionally, these can also be painted in the unit color in standard RAL 9010. Of course, ladders with and without a basket are also available in the same material.

Most railings are not assembled to avoid costly special transport. In most cases, the brackets for the railings have already been installed in the factory. This enables assembly personnel to assemble quickly and easily.

Your sales consultant will be happy to answer any further questions.

engineered to succeed°

CABERO Heatexchanger

CABERO is one of the leading producers of heat exchangers for refrigeration and air-conditioning technology. As independent supplier of innovative solutions, we have been making a name for ourselves world- wide since 1980 with well designed products and dynamic processes. The focus here is always on the goals of our customers: Our experienced engineers do not just follow short-lived trends, but it is their declared objective to perfectly support your intentions with state-of-the-art technology - flexibly, solution oriented and forward-looking

Whether it is refrigeration technology, air-conditioning technology, power plant or industrial cooling: We cooperate closely with operators, planners and refrigeration plant mechanics and know their needs. Our sales engineers define the optimum complete or individual solution with specifically developed software, naturally including a range of accessories, and they determine the operating costs for each design of the required system. Equally evident is the sustainability of our products with regard to production and operation. CABERO pays off – for your company as well as for the environment.

Our well attuned organisation designs, plans and realises customised solutions from the CABERO headquarters in Moorenweis near Munich. Furthermore, we have established state-of-the-art production facilities and warehouses in Germany, Hungary and China. Those choosing CABERO also choose unlimited service: We are at your service with sales offices in 22 national and international locations. This enables us to get active immediately if required.